The first order of business for the I/O Selectric is a visual inspection, both in and out of its outer shell. Other than a broken right margin lever, this didn't reveal any obvious faults. In fact, the machine looks pretty clean for a 50 year old device. Of course, the nasty foam under the keys has deteriorated to the point where it crumbles into sticky goo when you touch it, but some compressed air helped to quickly blow that out of the way.

Some dust and hardened grease...

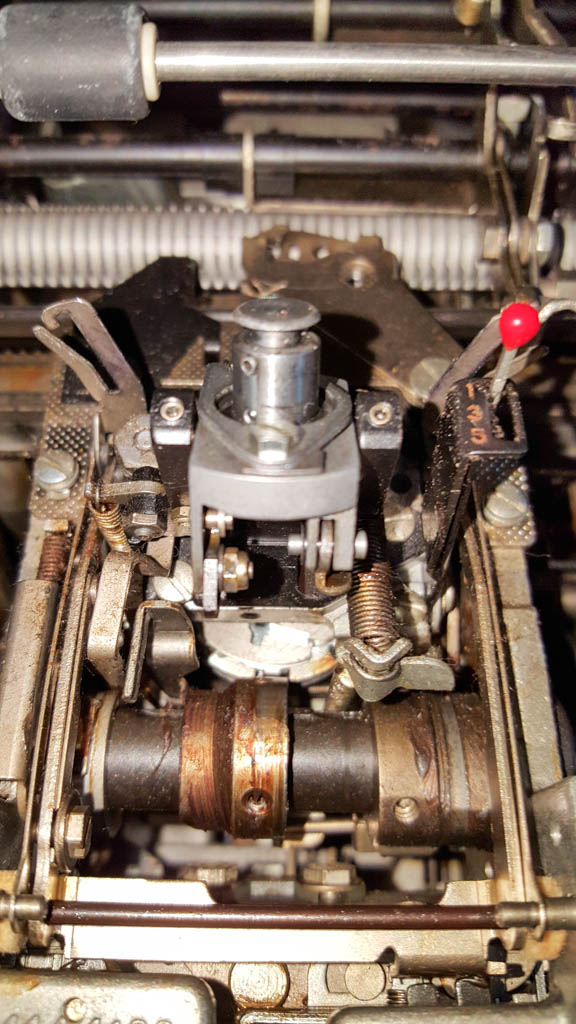

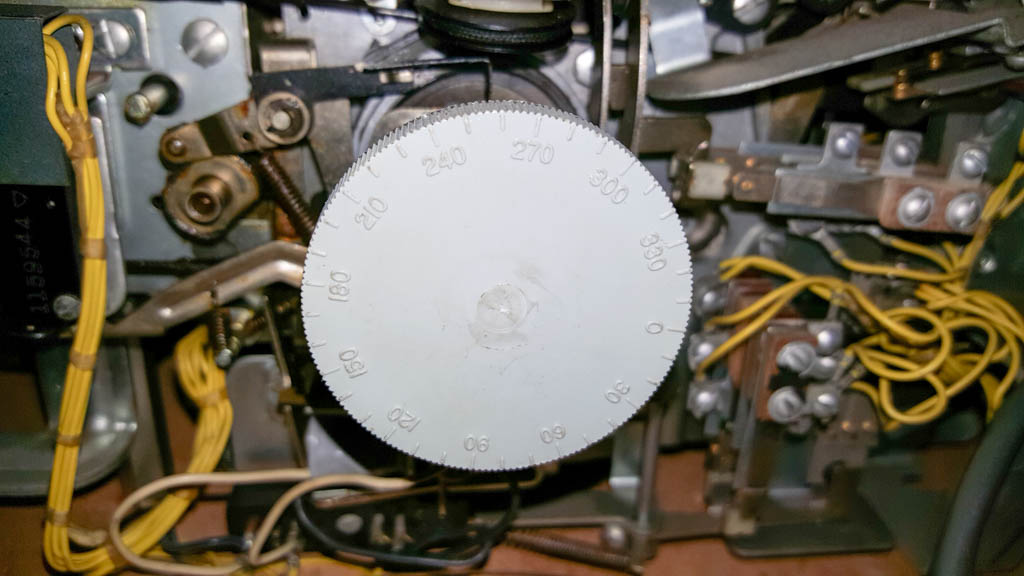

After that, it's time to fit the indispensable Hand Cycling Wheel to the right-hand side of the Operational Shaft, and try out some of the machine's operations while providing power by hand. Letting the motor run at this point would be too risky.

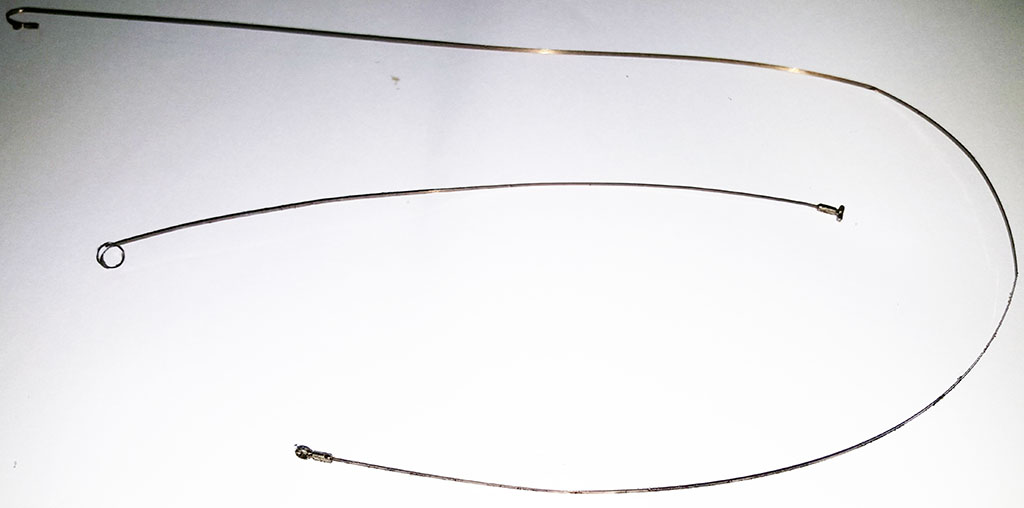

Overall, things seem ok; on some of the operations there's a bit of a delay, mainly due to cam followers returning to their original position sluggishly because of hardened grease and dust. Trying to half-cycle some characters revealed a more serious problem though, because while the golfball-shaped printing element was tilting correctly, it wasn't rotating very much. Further inspection showed that the rotate tape wasn't taut as it should be. The rotate tape is a very thin (0.06 mm) metal tape that pulls on a pulley to rotate the element, while a spring on the bottom of the pulley provides the necessary counter-force. Pulling on the rotate tape revealed that it had snapped into two pieces.

I found a supplier of these tapes in the US, but they charge an indecent amount for shipping to Europe. Fortunately, I happen to be in the US next month, so I've ordered some parts to be sent to a friend of mine there.

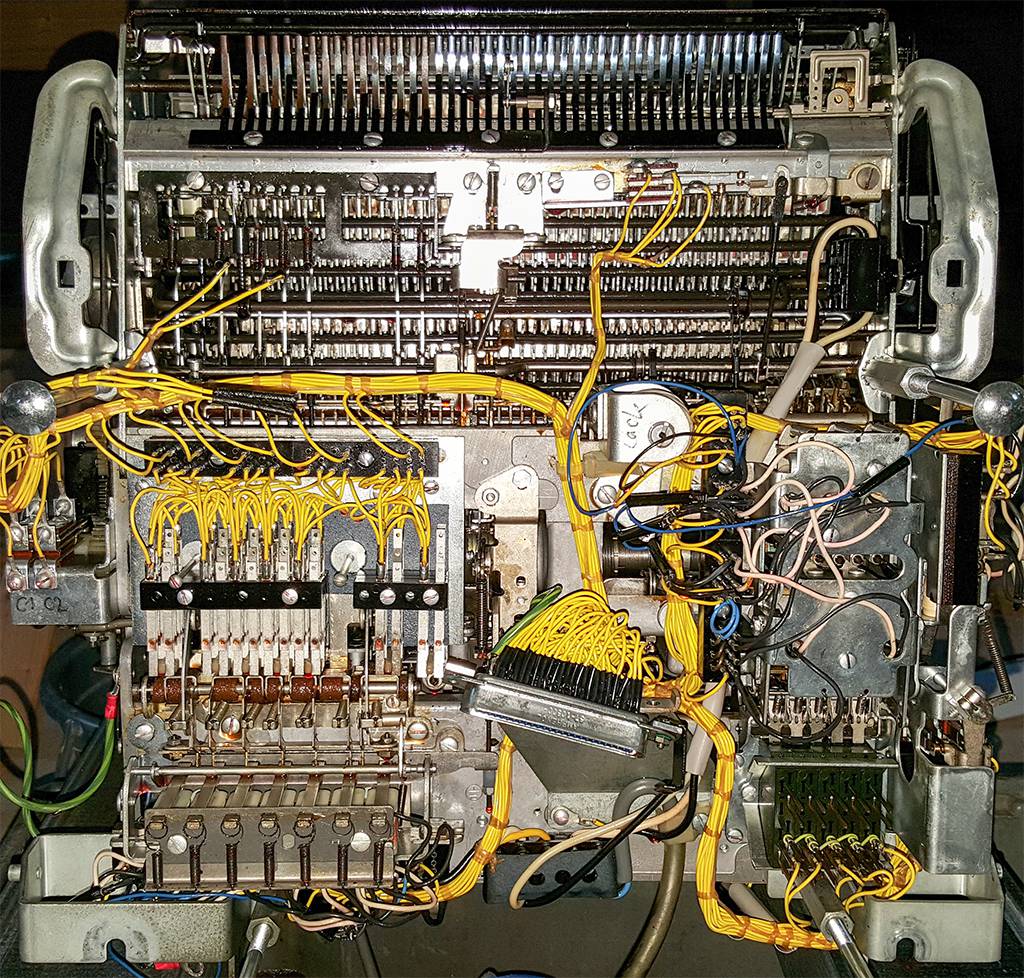

Until then, one thing I can do is clean the machine. The first stage of this is degreasing the machine, for which I use a spray bottle filled with Jizer, an industrial-strength automotive degreaser. I spray all parts of the machine liberally, then after letting it soak for a while, I use an assortment of small brushes to clean some of the loosened goo out, then re-spray with Jizer.

Bottom side during de-greasing

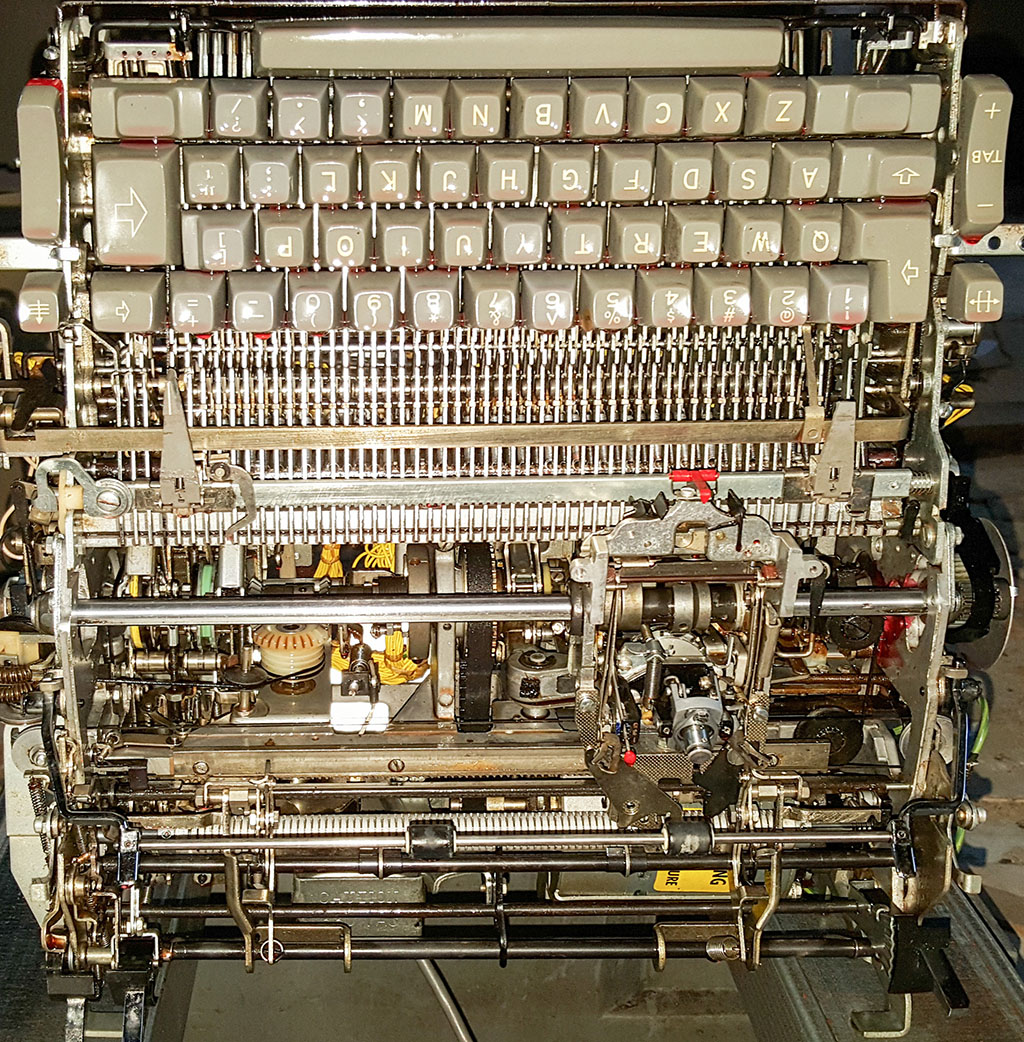

Top side during degreasing

The pink fluid in the images above is the Jizer. The machine is positioned over a drip-tray.